Screw foundations for solar carports: fast, efficient, and infrastructure-friendly

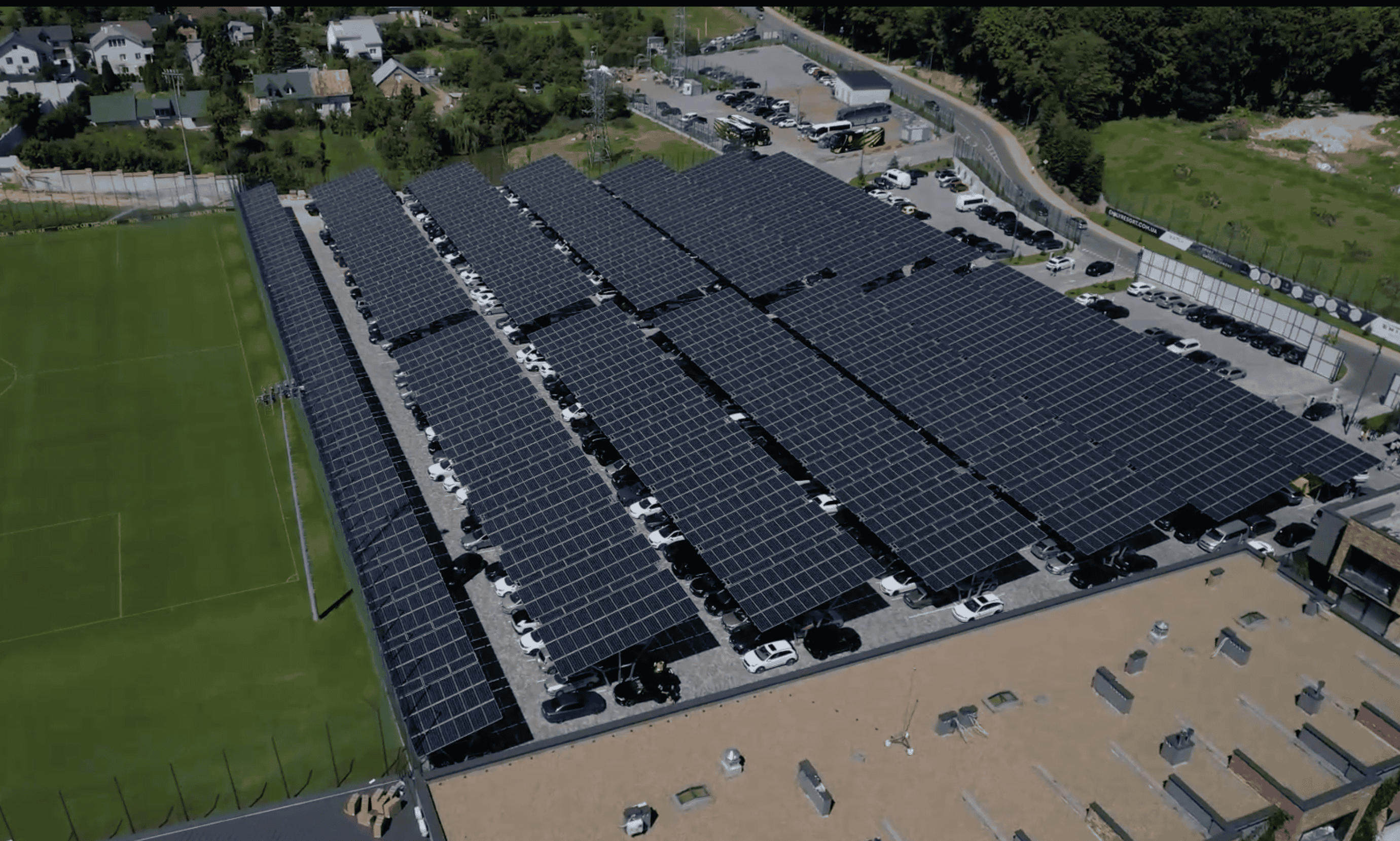

When planning a solar carport installation, one critical decision lies literally beneath the surface: the foundation. While conventional concrete bases remain a tried-and-true method, screw foundations offer compelling advantages – especially when reducing installation time, limiting infrastructure disruption, and optimizing overall project efficiency.

When planning a solar carport installation, one critical decision lies literally beneath the surface: the foundation. While conventional concrete bases remain a tried-and-true method, screw foundations offer compelling advantages – especially when reducing installation time, limiting infrastructure disruption, and optimizing overall project efficiency.

Minimal ground impact and reduced costs for PV carport installations

Traditional concrete foundations often require extensive groundwork, including excavation, soil removal, and disposal of paving materials like asphalt or concrete blocks. With screw foundations, there’s no need for such invasive steps. No excavation, no disposal logistics, and no need for large-scale construction equipment.

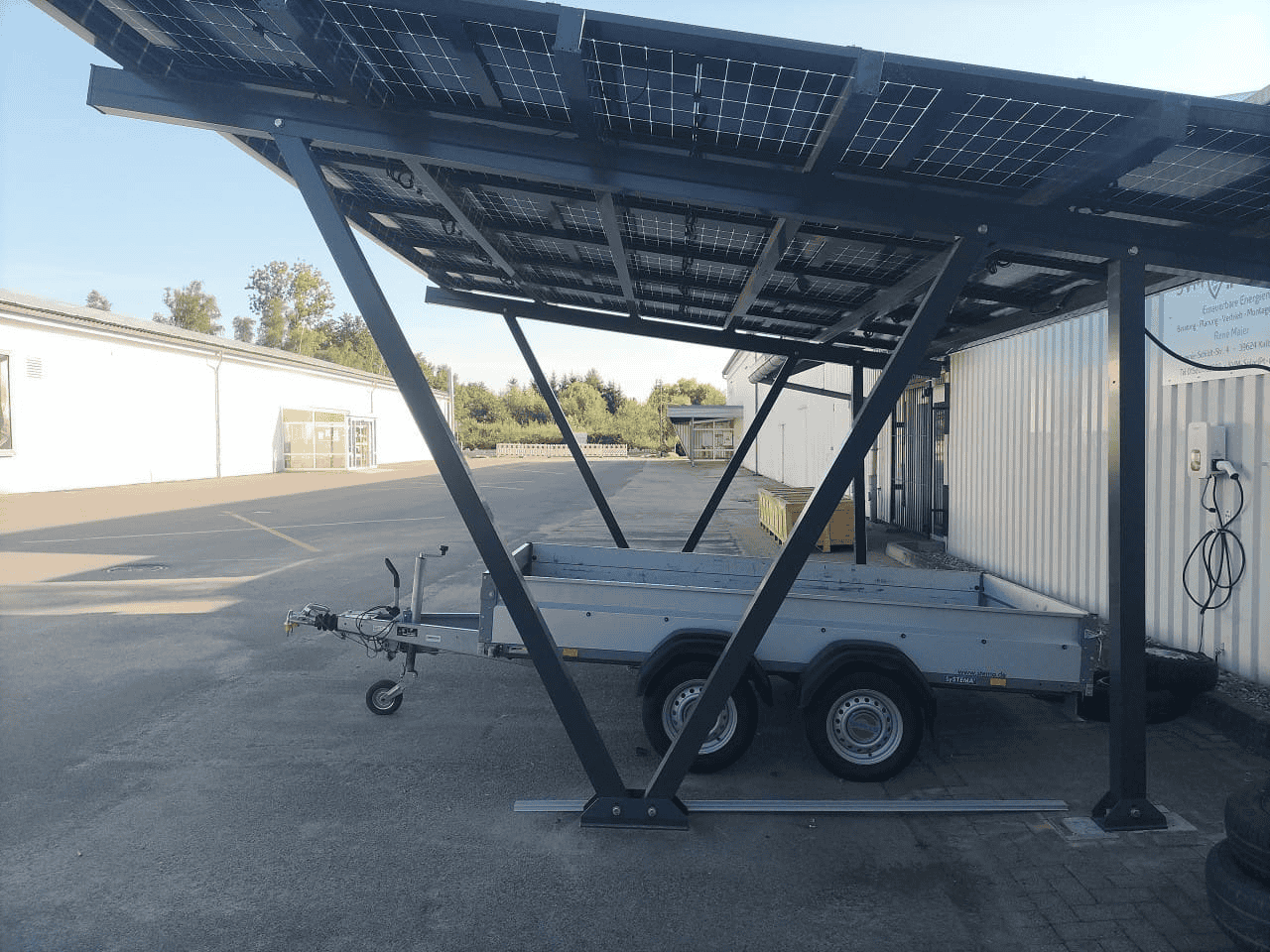

Instead, installation is performed using a compact crawler machine or a hydraulic drive attachment – making it ideal for solar carports on active sites such as public parking lots, logistics hubs, or company campuses. The result: lower installation costs, fewer emissions, and faster commissioning.

Foundation flexibility for most soil conditions

Ground screws used in PV carport projects can reach up to 8 meters in length, providing secure anchoring in a wide range of soil types. In roughly 90% of cases, there’s no need for conventional concrete – even in mixed soil profiles. For less stable subsoil, traditional reinforced foundations may still be necessary, but screw foundations cover the vast majority of use cases.

Fast installation without concrete curing time

Unlike concrete, screw foundations don’t require curing. As soon as they’re installed, the carport’s supporting structure and solar panels can be mounted immediately. This significantly reduces project timelines, allowing solar carport systems to go live quickly and restoring parking availability for employees, visitors, or logistics within a short window.

Proven durability with certified materials

At IBC SOLAR,  we rely on the ground screws of our qualified partners, which are made of galvanized steel (S235JR) and comply with the ISO 1461 standard. Depending on the screw length and ground conditions, they can handle loads of up to 2.7 tons per unit. The result is a safe, stable and durable base for your solar infrastructure. Plan your solar carport project with IBC SOLAR

we rely on the ground screws of our qualified partners, which are made of galvanized steel (S235JR) and comply with the ISO 1461 standard. Depending on the screw length and ground conditions, they can handle loads of up to 2.7 tons per unit. The result is a safe, stable and durable base for your solar infrastructure. Plan your solar carport project with IBC SOLAR

Whether you’re designing a commercial solar carport, outfitting a municipal parking lot, or developing a corporate energy solution, IBC SOLAR supports your project from design to installation. We help you select the right foundation, carport configuration, and PV modules for your location and goals.

Reach out now to start planning your customized solar carport solution:

📧 Sales-International@ibc-solar.com