Our new “Made in Germany” modules premiered at Intersolar 2025 in May – and the  response from installers and professional partners was overwhelming. In this post, we’ll show what makes the technology so special, where we stand in production, and when sales will begin.

response from installers and professional partners was overwhelming. In this post, we’ll show what makes the technology so special, where we stand in production, and when sales will begin.

The demands on modern solar modules are constantly increasing: in addition to high efficiency and reliability, factors such as sustainability, flexibility of use, and robustness also play a central role. Innovation in photovoltaics doesn’t just mean achieving higher efficiencies. It’s about rethinking solar modules: from technical design to integration into future-ready energy systems.

With the new bifacial IBC SOLAR “Made in Germany” module, we are addressing exactly these levels. The foundation is the advanced 2D matrix structure, which takes module technology to a new level.

The Technological Core: 2D Matrix Structure

Seamless cell layout without gaps

Instead of conventional busbars, wires, or solder joints, the solar cells are cut into fine strips and connected like masonry using conductive special adhesive. The result: a seamless cell layout without gaps, since the cells slightly overlap. Only fine vertical lines remain visible as a characteristic design element.

This flat matrix structure offers several functional advantages:

- More power thanks to smart technology: The combination of state-of-the-art TOPCon cells from leading manufacturers and the gapless 2D arrangement ensures extremely high packing density within standard module size – delivering top performance. The bifacial modules achieve outputs of up to 465 watts.

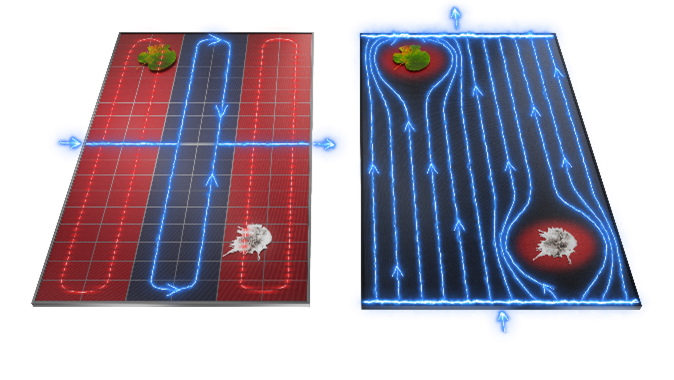

- Strong even in shade: While conventional modules block entire cell strings when shaded, the 2D matrix enables intelligent bypassing: current can flow two-dimensionally within the module, rerouting around shaded areas. This significantly boosts yields under real conditions – in tests by up to 70% with partial shading.

- Higher yield for the entire system: Better performance of individual modules under shading has a direct positive effect on the entire string, ensuring a simpler, more efficient overall system. In addition, the 2D matrix tolerates weaker-performing cells better than other technologies.

Development & Production “Made in Germany”

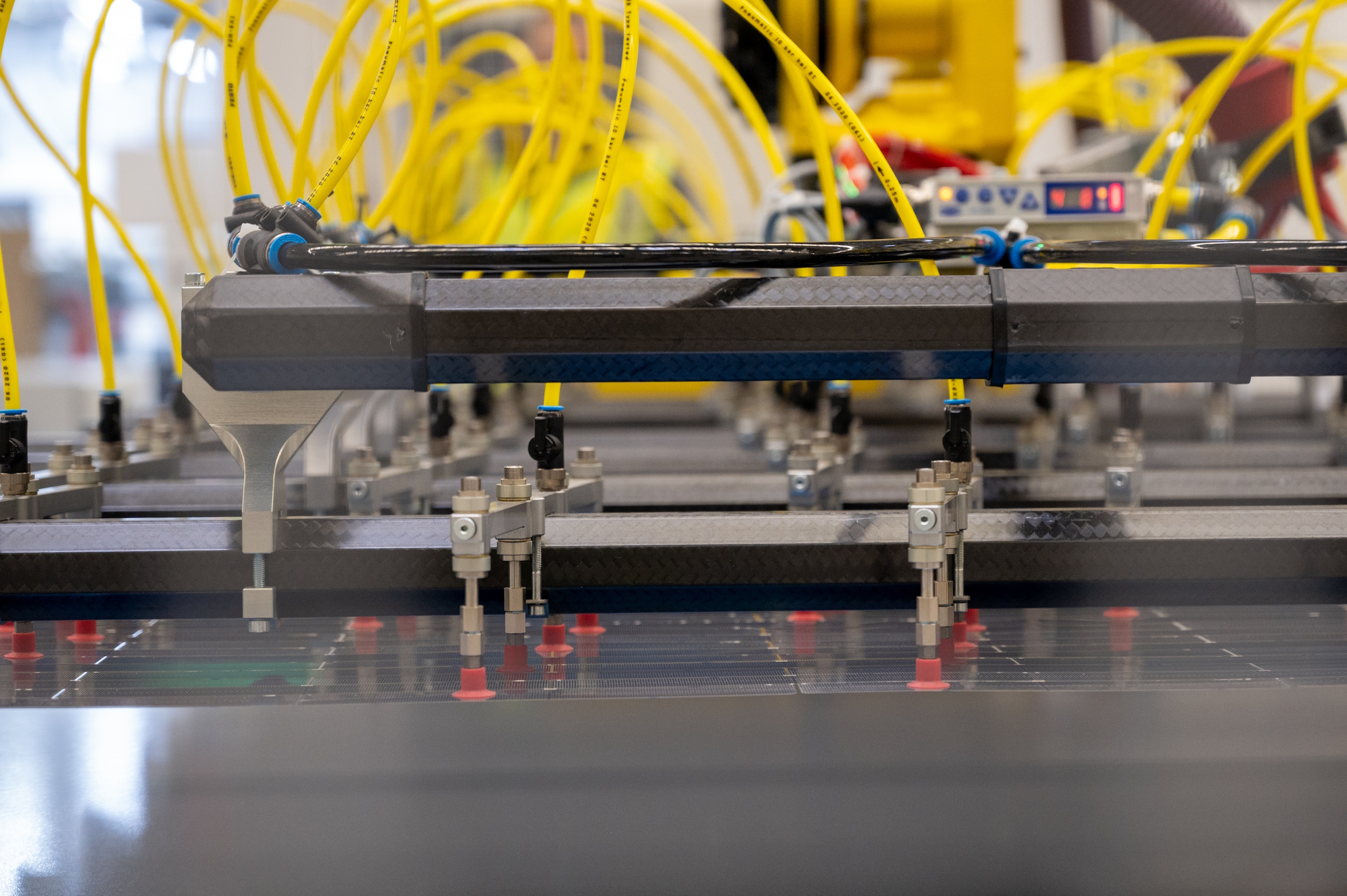

Our new “Made in Germany” module – the IBC Module Transparent DT-TX1 – is produced 100% in Germany. Specially developed, patented systems enable maximum precision in cell placement, ensuring consistent quality and process security.  But technology alone is not enough: research and production worked hand in hand. Using state-of-the-art electroluminescence measurements, every connection is checked – for maximum reliability.

But technology alone is not enough: research and production worked hand in hand. Using state-of-the-art electroluminescence measurements, every connection is checked – for maximum reliability.

From Test Lab to Series Production

As with every real innovation, 2D matrix technology started in controlled test environments. Early on – even before laser cutting the cells – it became clear: precise and reproducible arrangement is feasible. These insights formed the basis for the successful transfer into robust series processes.

Focus on Quality, Safety & Sustainability

Scaling up to series production prioritized process safety, worker protection, and sustainability. Early testing on key equipment optimized workflows, while environmentally friendly material decisions set new standards: the DT-TX1 is completely free of PFAS (per- and polyfluorinated alkyl substances = man-made “forever chemicals”) and lead – not only meeting current regulations but also making a clear contribution to a sustainable PV future.

In addition, 2×2 mm double glass and solder-free, automotive-tested cell connections ensure maximum resilience and durability of the new module.

A New Chapter for IBC SOLAR Modules

With the new “Made in Germany” DT-TX1 module, we are expanding our module lines with a true next-generation product. Technological innovation, deep manufacturing in Germany, and uncompromising quality make it a strong answer to the demands of the modern PV landscape.

👉 Discover all details about our “Made in Germany” module now in our online shop.