A walk through our test facility allows you to immerse yourself in the history of photovoltaics. Modules from many generations, some already a decade and a half old, show how technology has changed. Guest author and product manager René Schüler presents special test objects in a blog series and provides background knowledge to cell technologies and typical ageing effects. In the second part of our series he presents delamination, snail trails and yellowing.

A walk through our test facility allows you to immerse yourself in the history of photovoltaics. Modules from many generations, some already a decade and a half old, show how technology has changed. Guest author and product manager René Schüler presents special test objects in a blog series and provides background knowledge to cell technologies and typical ageing effects. In the second part of our series he presents delamination, snail trails and yellowing.

Discolouring and blistering

When comparing old and new modules, enhancements to the encapsulation materials are also clearly visible. Cracks in the rear film with material separation and visual changes such as “yellowing” and “browning” may only still be an issue for a few old PV veterans. These material changes have no longer been noticeable for a few years – especially due to the constant product enhancements of film manufacturers. We can operate and analyse older modules with “blistering” and “delamination” under real operating conditions. This enables statements to be made on the reliability and possible long-term consequences of the aforementioned error images.

Snail trails

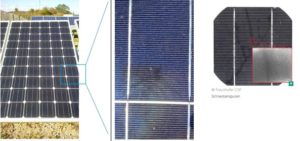

Another known PV phenomenon known as “snail trails” can only still be found in older modules at the test facility. Individual dark stains appear as brown strips on the solar cells a few weeks after their initial operation. These strictly local stains were visible as lines and referred to as “snail trails” due to their similarity to a slime trace. The visual phenomenon was often evident on cell edges and in microcracks. Silver nanoparticles were identified as the reason for the brownish discolouration using cause models including those at Fraunhofer CSP in Halle. An accumulation of nanoparticles formed above the encapsulation film benefited from special additives coming from used encapsulation materials. Quick and reliable material testing procedures were subsequently developed and the film manufacturers then optimised the relevant products. We have no longer been able to notice these visual changes with new module types for several years.

Read more: Part I – Polycrystalline modules through the ages