The global photovoltaic market has grown considerably in recent years. In concrete terms, this can already be seen in the preliminary product, the silicon wafer. Here, the expansion of production capacities in 2021 increased by an impressive 64 %. It is also evident that the supply is more diversified. Good profit margins have brought new market participants and driven both small and large companies to expand. Our module partners LONGI SOLAR at No. 1 and JINKO SOLAR at No. 3 among the world’s largest wafer manufacturers, together with Zhonghuan (No. 2) dominate global wafer capacity with more than 80%. Vertically integrated module manufacturers have also significantly increased their internal supply capacities. Thus, another 134 gigawatts of capacity could likely be added in 2022.

The global photovoltaic market has grown considerably in recent years. In concrete terms, this can already be seen in the preliminary product, the silicon wafer. Here, the expansion of production capacities in 2021 increased by an impressive 64 %. It is also evident that the supply is more diversified. Good profit margins have brought new market participants and driven both small and large companies to expand. Our module partners LONGI SOLAR at No. 1 and JINKO SOLAR at No. 3 among the world’s largest wafer manufacturers, together with Zhonghuan (No. 2) dominate global wafer capacity with more than 80%. Vertically integrated module manufacturers have also significantly increased their internal supply capacities. Thus, another 134 gigawatts of capacity could likely be added in 2022.

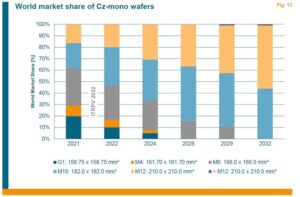

The market is moving in a specific direction. In 2021, the M6 (166 mm) wafer format was still the dominant size. In the coming months, the new GW cell productions based on n-type materials, primarily the “TOPCon solar cells”, will be produced on the wafer size M10 (182 mm) as the new standard variant. For the residential sector, the 54-cell half-cell format (i.e. 108 cut half-cells per module) must be added for the installation location Germany in order to get below the 2 m² glass cover area.

According to our technical assessment, the previous classic 60-cell variant in M6 format could disappear from the market even faster, contrary to current plans and publications. The first GW productions have already been completely converted to M10 in Q2. Taking into account the further expansion rates in the M10 format, in our opinion everything currently speaks in favour of the M10 variant completely replacing the previous M6 variant by the end of the year. According to external estimates, the already planned reductions of the M6 cells will at least be significantly reduced by another 20 – 30 percent, as in the recently published 13th edition of the International Roadmap for Photovoltaics, or ITRPV for short.

The module output of currently 370-380 Wp for M6 PERC will thus increase to 400-410 Wp in M10 wafer format. Through even more efficient cell concepts on an n-type basis, such as the TOPCon solar cells mentioned in 2021, the output may even increase to 420 Wp this year. At first glance, this is a positive development, because as we know, all market participants are happy about increasing efficiencies. What we will also see here, however, is a limitation in the trafficability of the module pallets and certain challenges with the module cardboard boxes in the distribution business due to the inclusion of the M10 wafers.

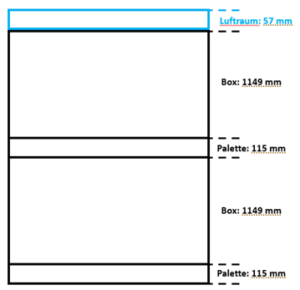

Challenges in the packaging area

At least the accessibility of the module pallets can no longer be realised with the classic hand pallet trucks due to reduced box heights of around 70 mm. At least 90 mm are required here. Due to the specified maximum entry height of 2585 mm for the 40’HQ containers, a corresponding reduction in the pallet height must therefore be made for vertical module transport. This limitation in turn ensures that only a certain stack height can be maintained. The influence on the module packaging specification is therefore enormous and, with 57 mm of air space, allows only little room for manoeuvre. The width of the packs also increases by more than 10 cm to a total of around 1149 mm. Thus, in view of the new module dimensions, a pallet can only be 115 mm high at most (currently and with the M6 wafers it is 140 mm). This pallet height in turn means that the block height is now only 70 mm, which is well below the required 90 mm.

In the end, lateral access with hand pallet trucks will no longer be possible with the larger module dimensions due to the M10 wafers, regardless of the manufacturer. The closed module boxes that are still available, at least at IBC SOLAR AG, as with the OS9-HC series, will most likely no longer be feasible in this form due to the new formats. However, there is some room for optimisation and corresponding possibilities. For example, we at IBC SOLAR are already working on a solution that ensures the stability and manageability necessary for distribution.

Have you ever experienced a failure during installation?

Hello, could you maybe specify what exactly you mean by that? Thank you and kind regards, IBC SOLAR