When you talk to the pioneers of the German PV industry, such as Mr. Udo Möhrstedt or the first participants of the symposium at Banz Monastery, one looks back at the early years with a sparkle in the eyes. A specific example is the comparison between the wafer sizes of the past and the present. The “wafer” is the starting material for the production of crystalline solar cells, which is only about 200 µm thick. Although there have been many adjustments over the years, the continuity has unfortunately disappeared. In recent months, countless new wafer sizes have appeared on the market. Something the PV industry has never experienced before. In addition, there is no uniform designation. With this article we would like to shed some light on the topic, and in addition to a review of the history of cell size, we want to compare the current common names.

When you talk to the pioneers of the German PV industry, such as Mr. Udo Möhrstedt or the first participants of the symposium at Banz Monastery, one looks back at the early years with a sparkle in the eyes. A specific example is the comparison between the wafer sizes of the past and the present. The “wafer” is the starting material for the production of crystalline solar cells, which is only about 200 µm thick. Although there have been many adjustments over the years, the continuity has unfortunately disappeared. In recent months, countless new wafer sizes have appeared on the market. Something the PV industry has never experienced before. In addition, there is no uniform designation. With this article we would like to shed some light on the topic, and in addition to a review of the history of cell size, we want to compare the current common names.

A look back at the past

The first modules had a power class of 48 watts in 1983. Here 36 cells with the dimensions 100 x 100 mm were used. The first modules had a power class of 48 watts in 1983. Here 36 cells with the dimensions 100 x 100 mm were used. This cell size was available on the market until about 1996. The first IBC Megaline modules with 120 watt, manufactured in the USA, were based on the dimensions 125 x 125 mm and were considered the standard size for many years. Also for manufacturers from South Korea and Japan. Thus the first 156 watt module, manufactured by BP, was also based on this 125 x 125 mm dimension.

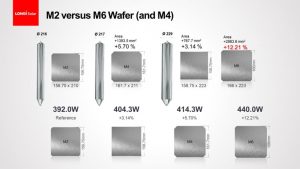

This was followed by the dimension of 156 mm, which has been defined as a standard for more than 10 years. For this module size, the term “M0” wafer size has established itself over the years. Eventually it was successively replaced by the introduction of the M2 variant with 156.75 mm. With reference to these dimensions, the average module size was 1640 or 1650 x 992 mm (length x width) for a 60-cell solid cell module.

New and chaotic times – spoilt for choice

The times where module dimensions have been on the market over a longer period of time and were set as standard are now over. New wafer sizes are constantly appearing on the market, so that the term “standard” can no longer be defined uniformly. In this regard, three new wafer sizes appeared on the market in 2019 alone.

Let’s start with the M3 variant, for example. With this type, the wafers were again extended by 2 mm to a total size of 158.75 mm. It is important to mention that in this case only the module length increases due to the use of half-cell technology (HC). The module width remains the same in comparison to a full cell module. IBC modules that are based on this M3 wafer size are the IBC MonoSol MS-HC and the IBC MonoSol RS-HCC.

At Intersolar 2019, we had already introduced the black IBC MonoSol ZL-MB Black with the wafer size M4. At that time, our Taiwanese cell manufacturer went straight from M2 to the M4 with a size of 161.7 mm in order to only make necessary investment purchases once, together with the multi busbar variant.

At the end of Q3/2019, Longi Solar, the world’s largest mono wafer manufacturer, launched another variant on the market for the first time: M6. This has a wafer size of 166 mm. This results in a module size of 1776 x 1052 mm for the half-cell variant. This variant can be found in our portfolio in the new IBC MonoSol OS6-HC.

The end in sight?

For the year 2020, the M3 format will in all probability become the standard measure in the module range in Europe. However, due to Longi’s enormous wafer capacity, other cell and module manufacturers will and must include the M6 variant in their portfolio in addition to the M2 and M3. At the world’s largest solar trade fair SNEC in Shanghai in the summer of 2019, some manufacturers went even one step further and presented the introduction of a 210 mm variant, the so-called M12. However, an application of such module sizes in Europe is currently unlikely due to the current mounting concepts.

This means that all players in the PV industry will have to contend with a mix of various module sizes in the upcoming months – from M2 (156, 75) and M3 (158.75) to M6 (166). It is exciting to see which variant will eventually win the race!

Author: René Schüler (Product Manager)

Thanks for sharing this info , keep posting

Varun Sethupathi

Thanks for your positive feedback.

Thanks for giving us the correct perspective through your article, its really helpful and means to me. I wish to read more articles related to this.

Thanks for your positive feedback.