How to use sector coupling effectively

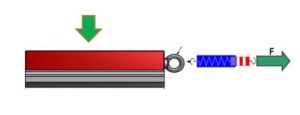

Power-to-heat: heating with electricity has long been considered uneconomical and harmful to the climate. With the energy transition, the focus is once again on heat generation using self-generated green electricity. Both efficiency and cost-effectiveness are now under good auspices. Sector coupling is moving more and more into the spotlight and is already showing what our future green energy system can look like. (more…)