Our year 2019 in review

The year is drawing to a close. Just before Christmas, we take the time for a review of the solar year 2019! Read about the highlights we have experienced over the past 12 months. (more…)

The year is drawing to a close. Just before Christmas, we take the time for a review of the solar year 2019! Read about the highlights we have experienced over the past 12 months. (more…)

The year is drawing to a close. Just before Christmas, we take the time for a review of the solar year 2019! Read about the highlights we have experienced over the past 12 months. (more…)

The year is drawing to a close. Just before Christmas, we take the time for a review of the solar year 2019! Read about the highlights we have experienced over the past 12 months. (more…)

When you talk to the pioneers of the German PV industry, such as Mr. Udo Möhrstedt or the first participants of the symposium at Banz Monastery, one looks back at the early years with a sparkle in the eyes. A specific example is the comparison between the wafer sizes of the past and the present. The “wafer” is the starting material for the production of crystalline solar cells, which is only about 200 µm thick. Although there have been many adjustments over the years, the continuity has unfortunately disappeared. In recent months, countless new wafer sizes have appeared on the market. Something the PV industry has never experienced before. In addition, there is no uniform designation. With this article we would like to shed some light on the topic, and in addition to a review of the history of cell size, we want to compare the current common names. (more…)

When you talk to the pioneers of the German PV industry, such as Mr. Udo Möhrstedt or the first participants of the symposium at Banz Monastery, one looks back at the early years with a sparkle in the eyes. A specific example is the comparison between the wafer sizes of the past and the present. The “wafer” is the starting material for the production of crystalline solar cells, which is only about 200 µm thick. Although there have been many adjustments over the years, the continuity has unfortunately disappeared. In recent months, countless new wafer sizes have appeared on the market. Something the PV industry has never experienced before. In addition, there is no uniform designation. With this article we would like to shed some light on the topic, and in addition to a review of the history of cell size, we want to compare the current common names. (more…)

On Sunday, the 23.06.2019 the day had arrived. At 04h00 in the morning 14 students of the State Vocational School Lichtenfels and myself started the upcoming adventure at Nuremberg Airport for the next two weeks: A foreign internship in Plymouth. But before I tell you more about my experiences in England, first to me: My name is Jennifer Blodgett and I am an industrial sales representative trainee, at IBC SOLAR since September 2018. (more…)

On Sunday, the 23.06.2019 the day had arrived. At 04h00 in the morning 14 students of the State Vocational School Lichtenfels and myself started the upcoming adventure at Nuremberg Airport for the next two weeks: A foreign internship in Plymouth. But before I tell you more about my experiences in England, first to me: My name is Jennifer Blodgett and I am an industrial sales representative trainee, at IBC SOLAR since September 2018. (more…)

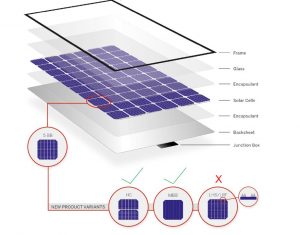

The photovoltaic market has increased significantly over the last decade. In 2015, the annual PV installation was over 50 GW and the solar cells made with Multi Crystalline Silicon (mc-Si) had a market share of nearly 60 %. This year, however, the majority of European countries noticed a significant switch to Mono Crystalline Silicon with ratios of ~70 % in comparison to 30 % mc-Si. Regardless of the technology, one aspect is absolutely clear: the market is still going the direction where customers worldwide require higher efficiencies. The prices, however, have to stabilise or should get lower. By fulling this demand, cell and solar module producers are required to provide a solution to offer higher efficiencies at the same or lower level of prizing. In Sep 2018 we introduced you to our new module technologies which includes Half Cell, Multi Busbar or optimized cell connector like LRF. This time we want to take a closer look the Cast Mono technology. (more…)

The photovoltaic market has increased significantly over the last decade. In 2015, the annual PV installation was over 50 GW and the solar cells made with Multi Crystalline Silicon (mc-Si) had a market share of nearly 60 %. This year, however, the majority of European countries noticed a significant switch to Mono Crystalline Silicon with ratios of ~70 % in comparison to 30 % mc-Si. Regardless of the technology, one aspect is absolutely clear: the market is still going the direction where customers worldwide require higher efficiencies. The prices, however, have to stabilise or should get lower. By fulling this demand, cell and solar module producers are required to provide a solution to offer higher efficiencies at the same or lower level of prizing. In Sep 2018 we introduced you to our new module technologies which includes Half Cell, Multi Busbar or optimized cell connector like LRF. This time we want to take a closer look the Cast Mono technology. (more…)

A walk through our test facility allows you to immerse yourself in the history of photovoltaics. Many previous generation modules , some already now a decade and a half old, show how technology has advanced. In our blog series, guest author and product manager René Schüler presents special test objects and reports in our latest contribution together with Manuel Baier about the latest system at our facility. In addition to the previous crystalline poly- and mono- solar modules, so-called bifacial modules have now also been inspected at the open-space test facility. (more…)

A walk through our test facility allows you to immerse yourself in the history of photovoltaics. Many previous generation modules , some already now a decade and a half old, show how technology has advanced. In our blog series, guest author and product manager René Schüler presents special test objects and reports in our latest contribution together with Manuel Baier about the latest system at our facility. In addition to the previous crystalline poly- and mono- solar modules, so-called bifacial modules have now also been inspected at the open-space test facility. (more…)